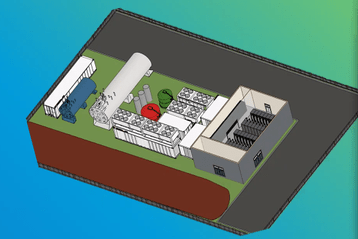

EdgeCloudLink (ECL), a firm in California plans to provide off-grid 3D Printed Data Centers Powered by Hydrogen and, using 3D-printed concrete structures.

The new business is utilizing a construction 3D printer and a nearby building services firm to construct its first data centre at its Mountain View, California, headquarters. It will use a proprietary liquid cooling system and be fueled by hydrogen delivered from a nearby source, which will eliminate the need for diesel generators

How 3d printed modular data centres different from existing one and what challenge ECL is solving?

Operating data centres can be expensive due to a variety of factors, such as the environment and the erratic nature of variable expenses (such as electricity). In warmer climates, the costs of cooling data centres can add up quickly.

Running a data centre can be costly due to the extra expenses on fuel and electricity, which can vary depending on geopolitical conditions.

By creating 3d printed modular data centres that be put together from printed blocks and have each standard unit be able to produce 1-2 MW of power, ECL hopes to cut costs. On-site hydrogen production will provide the energy.

To create larger sites, the ECL unit can be used many times. ECL has simplified scalability by optimising the speed and build cost of a single block. With each whole block being segregated for electricity, cooling, security, fire suppression, and operations, the company is able to construct according to the needs of the customer, thanks to the modular idea.

ECL announced hydrogen-powered off-grid 3d printed data center

$7 million in support for a new modular net zero proposal from Molex and Hyperwise

EdgeCloudLink (ECL), a firm offering data centres as a service, intends to provide hydrogen-powered off-grid modular data centres that are created in 1MW pieces using 3D printing technology.

The new business is utilising a construction 3D printer and a nearby building services firm to construct its first data centre at its Mountain View, California, headquarters. According to ECL, 3d printed modular data centres won’t require diesel generators and will be fueled by hydrogen provided from a nearby source and cooled using a patented liquid cooling system.

Do you know edgecloudlink 3d printed data center is Carbon-free and zero emission?

In order to build a community-integrated data centre with zero emissions and water use, ECL 3d printed data center choose to build a totally sustainable data centre in 2023 – not because it’s simple, but because it’s difficult, the author quotes John F. Kennedy as saying of the moon programme. Molex and Hyperwise have contributed $7 million to the business.

According to Bachar, ECL’s strategy will enable it to quickly—within six months—build out its data centre capacity, and the company’s small footprint will make it easy for it to get past zoning and safety requirements. With the use of a 3D printer and green building materials, each 1MW unit will be constructed as needed. A nearby hydrogen supply will fill an on-site tank with hydrogen to power the hydrogen fuel cells that will power it.

The first 1MW plant we’re developing will be visible to everyone in Mountain View, California, according to Bachar. We made the decision to cooperate with Mountain View because it is regarded as a difficult city to deal with. In our opinion, if we could control Mountain View, California, we could probably control it everywhere else on the planet.

Efficiency and effectiveness of EdgeCloudLink 3d printed data center

Bachar claims that ECL can create data centres for half as much as it now costs to build them, which ranges between $12 to $15 million per MW. It is therefore less expensive than current colocation facilities. Additionally, it undercuts bare metal solutions from cloud service providers with effective hyper-scale facilities because their exorbitant markup currently fuels cloud scepticism.

Each data centre will feature a hydrogen tank, fuel cells for its primary power source, and batteries for backup power. For further reliability, it may, where appropriate, be connected to the local grid.

The 3d printed data centers powered by hydrogencentre will have additional fuel cell capacity, and because the units are modular, the impact of any failure will be minimal. “We completely overdesigned the system. Everything is 2N, or 2(N+1), allowing for a Tier IV reliability level of six nines.”

ECL would construct additional 3d printed modular data centers on the property for larger data centres, each of which would be connected to a central meet-me room for network services. There will be independent hydrogen power sources in each module “The beauty of this is that it is modular and the individual blocks may be assembled in any way we like. Due to the independence of each block, we refer to it as private colocation.”

Customers will have the choice of running their own data centre, having ECL manage it, or operating as a joint venture when they order a data centre.

Why 3D printing technique?

ECL 3d printed data center claimed that compact data centres, which meet ECL’s modular design, are unexpectedly well suited for construction 3D printers: “We can print blocks one at a time, using sustainable concrete, with zero waste.” When no building is being done at a location, ECL intends to give the construction printer to the neighbourhood to be used to build homes or other facilities.

Building its Mountain View site with partners is ECL’s strategy: “Their specifications are considerably more straightforward than those of a home, which they are building. Simply put, a data centre is a rectangle. We don’t require complicated equipment. We have no windows.”

The neighbourhood partners aid in guiding construction projects through seismic and zoning requirements in California. The shell is made of two thin, insulated walls. “It’s a very strong and insulated structure, which means that the elements outside have a considerably lower impact on the inside,” says the architect.

ECL will possess its own 3D printers after the initial building and train personnel on how to use them. “A construction firm is not necessary for us. It requires only three individuals to actually print a structure.”

3d printed data centers are powered by hydrogen

With Microsoft testing fuel cells to provide the equivalent of a 3MW generator in 2022, hydrogen is now considered an exotic option making its way into backup. The Biden administration’s Inflation Reduction Act prioritises developing a hydrogen economy, and Bachar believes hydrogen is capable of more than this: “There is a whole effort in the US right now to build networks of hydrogen generation hubs that will be able to deliver by truck with no more than a two-hour drive.”

Although the supply of hydrogen in Europe is spotty, he is optimistic that it will improve: “We honestly feel that the hydrogen availability issue is not going to be a huge concern.”

The ECL 3d printed data center will be able to produce hydrogen and donate it to the local economy wherever there is additional cheap power owing to overproduction of renewable sources, according to Bachar.

What would be the cost of 3d printed modular data centres?

He estimates that the cost of hydrogen should be around $4 per kilogramme: “If it’s available for $3 per kilogramme, that comes out to 20 cents per kilowatt hour,” he says, which is less expensive than the energy that many data centres can currently purchase. The facilities will still be cost-effective even if the price increases to $6 because of their effective cooling.

FAQ

What is ECL?

EdgeCloudLink (ECL) is a technology related to Edge Computing and the Internet of Things (IoT). It refers to a platform that connects devices at the edge of a network with cloud-based applications and services. The aim of EdgeCloudLink is to enable low-latency, real-time data processing and decision-making at the edge of a network, reducing the need for data to be transmitted to a central location for processing

What is 3D Printing?

3D Printing, also known as Additive Manufacturing, is a process of creating a three-dimensional solid object from a digital model by adding material layer by layer.

By Q2 of 2023, the pilot should be ready. For more information, visit ECL site, here.

Bookmark us for more 3d printing related tips and tricks follow @futuretechverse and @futuretechpaedia on facebook and instagram. Did you check our latest 3D bioprinting post, if not must Visit futuretechverse