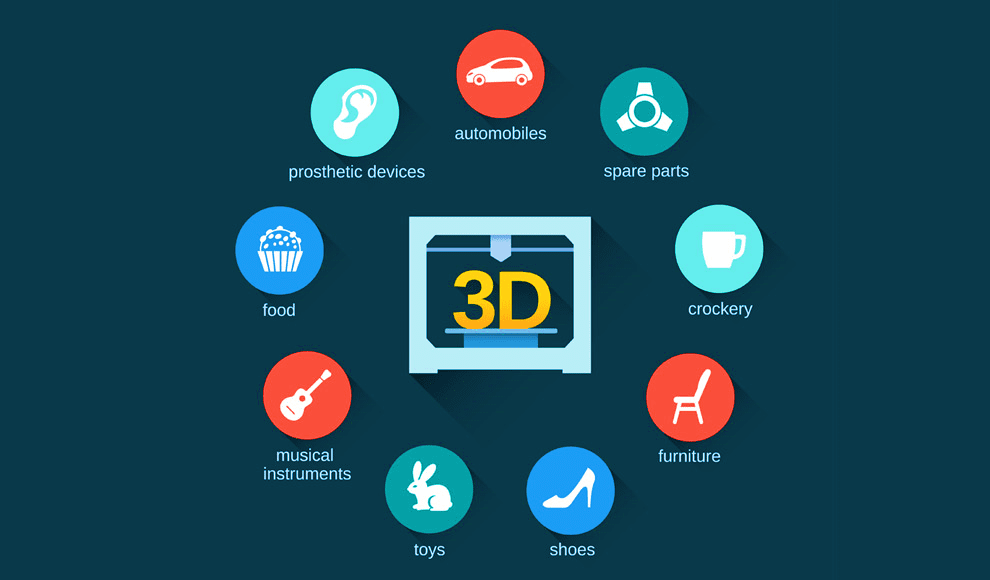

In the last few years 3D printing has developed significantly and can now perform vital roles in many applications, now a days it is widely used in multiple fields like manufacturing, medicine, architecture, custom art, and design.

For a long time, the issue with additive manufacturing (3D printing) was its high entry costs, which does not allow profitable implementation to mass-production when compared to standard processes. However, recent market trends spotted have found its usage and implementation with minimal cost. The additive manufacturing (3D printing) market has shown some of the quickest growth within the manufacturing and production industry in recent years.

3D printing facts:

- The orthopaedics industry (3D printing ) was valued at $691 million in 2018 and is predicted by SmarTech Analysis to grow upto $3.7 billion market by 2027.

- The 3D printing in healthcare and medical sector including materials, services, software and hardware, is currently estimated to be worth $1.25 billion, according to SmarTech Analysis.

- In the defense and aerospace industry, 3d printing is widely used for prototyping (72 per cent), followed by repair (44 per cent), research and development (43 per cent) and production parts (39 per cent).

Next generation stem education system is 3D printing

Now a days schools are incorporating 3D printing methods into their curriculums. The benefits of 3D printing for education are, it helps better prepare students for their future by allowing students to create prototypes without the need for expensive tooling.

3D printing in Education

Students learn about 3D printing applications by designing and producing models they can actually hold which enhance the education system to next level.

3D printing bridges the gap between ideation and reality, it is allowing for the creation of those ideas/images in the physical, 3-dimensional world.

Now a days 3D printers are commonly found in classrooms and public libraries. Universities have 3D printers available for students to use in classes and curriculum projects.

3D printing tools are also revolutionizing STEM education by offering the ability for low-cost rapid prototyping, and fabricating low-cost high-quality scientific equipment from open hardware designs by students in the classroom

Students learn about a variety of 3D printing applications by exploring design, engineering, and architectural principles along with that they are able to duplicate museum items like fossils and historical artifacts to study in the classroom without damaging delicate collections. 3D printing enables to gain a new, 3-dimensional perspective on topographic maps.

3D printing allows to construct Complex working parts by Graphic designers. Biology students can create and study cross-sections of organs in the human body as well as other biological specimens. Chemistry students can make 3D models chemical compounds and molecules

2. 3d printing in automotive industry

PROTOTYPING AND MANUFACTURING – no more hindrance in customization and high input cost 3D printing was first developed to utilize it in faster prototyping. Traditional injection-molded prototype takes weeks to produce a single mold, the same we can create in single day using 3d printing with freedom of multiple iteration.

3D Printing automotive industry

So , we can say that, 3D printing technology greatly reduces the lead times required in traditional manufacturing, allowing us to save time as well as cost. The automotive and aerospace industries are one of the major industries involved in manufacturing and taking advantage of advances in 3D printing technologies.

Traditional manufacturing is the cost-effective at large volumes, however in situations where a product is not going to be mass produced, 3D printing (aka ‘additive manufacturing’ in manufacturing circles) is the right choice as it allows for the relatively inexpensive production of a product in much smaller volumes or on a case-by-case basis.

In this same vein, advances in rapid prototyping (RP) technology has also given rise to the development of materials and processes, such as Direct Metal Laser Sintering (DMLS) and Selective Laser Sintering (SLS) that are suitable for the manufacture of the final version of a product, not just its prototype, called Rapid Manufacturing.

With cloud computing technologies so prevalent today, there are several 3D Printing companies now a day that offer cloud-based additive manufacturing services where consumers can build/ order parts and objects remotely without the expense of purchasing a 3D printer. Now a day this technology is used to create complete 3D printed car.

Companies now offer mass customization services as well where consumers can customize objects through simple web-based customization software and ordering the resulting items – mobile phone cases for example

3. 3d printing in medical – New Era, now organ and prosthetic can be printed, do you know how?

In Medical industry bioprinting is one of the major applications use now a days, where biomaterials such as growth factors and cells are combined to create tissue-like structures imitating their natural counterparts and helps in creating prosthetics.

3D Printing in Medical Industry

Additive manufacturing (3D printing) prosthetics exemplify 3D printing’s versatility. It is difficult and expensive to produce prosthetics that fit a patient, however 3D Printing overcomes that challenge. Using 3 D printing measured prosthetics can be modeled and printed at significantly lower cost.

In medical sector 3D printing applications are also used for producing metal orthopedic implants. Due to 3D printing’s capabilities for creating porous surfaces, these types of implants easily integrate with the patient’s own natural bones, allowing them to grow into the implant.

There have been successful cases of 3D printing application in medical field, where in a patient receiving a titanium pelvis implant, another getting a new titanium lower jaw.

With the help of Bioprinting technology Artificial organs are now printed. It helps in solving organ failure issues in patients faster, which is important to both the patient and his/her family and to healthcare systems.

3D printed tissues have been developed now a days which is cost effective and ethical means of helping to test and identify the side effects of drugs and validating safe dosages.

4. 3d printing in construction: No more brick and tiles to build house, moving to next generation house

Construction 3D printing offers various technologies that use 3D printing to fabricating buildings or construction components.

3D printing applications and materials that are used in construction include extrusion. In this we use materials like concrete/cement, wax, foam, polymer bond, reactive bond etc.

3D printing in construction has a wide array of applications in the industrial, commercial, private and public sectors. Advantages of these technologies include allowing more accurate and complex design, faster construction, lower labor costs and less waste

3D Printing Construction

Russia (Yaroslavl) constructed first fully completed 3D Printed residential building in 2017. It includes 600 elements which were printed in a shop and later assembled on site, the total area of 298.5 sq meters (3213 sq ft) is assembled including roof and interior.

The project represents the first time in the world the entire technological cycle had passed building permit and requirements, from design, registration, to connection of all engineering systems.

Concrete 3D printing technique has been in development since the 1990s. It allows faster construction with less input cost for constructing buildings and other structures. In this process, large-scale 3D printers designed specifically for printing concrete can pour foundations and build walls onsite. The other way is, at first we print modular concrete sections in factory and later assembled on the job site.

The first pedestrian bridge was 3D printed in Alcobendas, Madrid, Spain in 2016. In this printing micro-reinforced concrete is used throughout the dimension followed by length of 12 meters (39 ft) and width of 1.75 meters (5.7 ft). The bridge illustrates the perfect complexities in the forms of nature. It was developed by both parametric (using a set of rules, relationships and value that guide the design) and computational design, allowing maximizing structural performance along with optimal distribution of materials. It was a great milestone in the international construction industry

3D printed Bridge | Courtesy- IAAC.net

Also, It is the first large-scale application of 3D printing technology in the sector of civil engineering in a public space.

5. 3d printing space – No more need to carry raw materials to create habitat?

As a futuristic concept, NASA is also taking its step towards 3d printing. It is being studied as a technology for constructing extraterrestrial habitats on the Moon or Mars. NASA is working on creating building structures with enclosed inflatable habitats for housing human occupants inside the hard-shell lunar structures. So, to create this habitat only ten percent of the structure need to transport from Earth, and rest 90% raw material is the lunar material. Using this technology NASA could save on transporting cost of raw material.

Courtesy- NASA.gov

6. How 3D printed ring and jewelry revolutionize ART AND JEWELRY industry?

3D printing also revolutionize the art and jewelry making industry – it gives freedom to customize and print complex jewelry design. Also 3D printers allow jewelry makers to experiment with different designs, which is not possible with traditional jewelry making methods. It lower down the production cost, gives freedom and benefits of limitless customization as per individual requirement. In this the materials we can use are PLA (polylactic acid filament), gold or platinum.

3D printed Jewelry

So, we can say 3D printing has served to inspire artists all over the world. With metal 3D printing especially, artists now can create beautiful intricate pieces with maximum customization.

Using powder binding 3D printing technology the mysterious and famous British street artist Bansksy’s works have rendered from 2D to 3D

Recently, the Prado Museum organized an exhibition of 3D paintings by well-known artists. The purpose was to allow visually impaired people to feel this fantastic art of works that were previously inaccessible to them.

Conclusion:

These are just a few examples of the countless ways, from education to industry to medicine to the arts, that 3D printing technologies impact our world today completely.Stay tuned with futuretechverse blog and sign our newsletter for latest technology update.

FAQ:

What are the benefits of additive manufacturing?

Additive manufacturing offers several benefits, including the ability to create complex geometries that would be difficult or impossible to produce using traditional manufacturing methods. It also enables faster prototyping and customization, reduces waste, and can be more cost-effective for small production runs.

What materials can be used in additive manufacturing?

Additive manufacturing can be used with a variety of materials, including plastics, metals, ceramics, and even food and living tissues. The specific materials that can be used depend on the type of additive manufacturing process being used.

What industries use additive manufacturing?

Additive manufacturing is used in a wide range of industries, including aerospace, automotive, medical, consumer products, and architecture. It is particularly useful for prototyping and producing customized or low-volume parts.

Can additive manufacturing be used for large-scale production?

While additive manufacturing is often associated with prototyping and low-volume production runs, it can also be used for large-scale production. However, the economics of using additive manufacturing for large-scale production may depend on the specific application and the materials being used.